My Cart

Your Cart is Currently Empty

NEXT WORKING DAY DELIVERY - ORDER BEFORE 2.30PM

The alloy wheels are quite possibly the most essential part of the vehicle and certainly the first area you should be turning your attention to when it's time to clean. Cleaning your wheels is as much about the visual look of the vehicle as it is about the safety and integrity of the wheel.

If you fail to maintain your wheels, this could result in pitting or surface abrasion. Another reason to regularly clean your alloy wheels is to visually check the condition of the tyres, tyre walls and, of course, the brake pads and callipers. This will naturally happen when you are cleaning the wheels as your eyes cast across the surfaces while cleaning.

As the wheels and tyres are the only part of the vehicle that comes into contact with the road surfaces, they naturally and quickly become the dirtiest area of the vehicle. This, coupled with heat generated from the brakes, helps to bake this dirt and grime onto the wheel surfaces.

So, how do we effectively and efficiently clean our alloy wheels?

To start, take your Duel Wheel Bucket, apply 15ml of Bahama Blue Shampoo, and then fill it with water. Add your EZ Detail Go Brush, EZ Detail Wheel Brush, Duel Tyre Scrubbing Brush and detailing brush to the bucket.

The chemical products, you will need to get you Alloy wheels clean,

Nitty Gritty - Pre Wash & Degreaser

Cleanse - Tyre Cleaner

Axis - Non-Acidic Wheel Cleaner

BlackJack - Glue & Tar Remover

Toxin - Iron Fallout Remover

Profile - Tyre & Trim Dressing

Duel Tyre Dressing Applicator

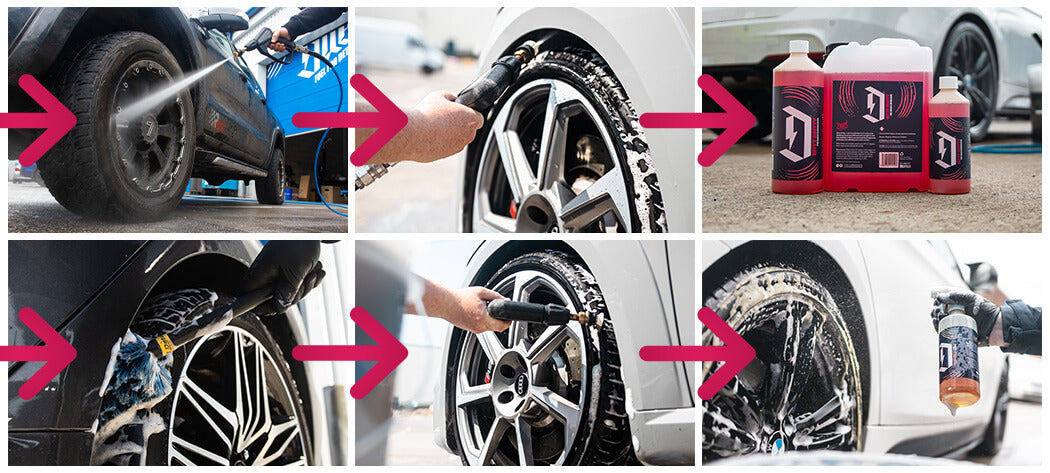

First, we need to rinse the wheel surface and the wheel arch thoroughly; a pressure washer is perfect for this. Wheel arches collect mud and grime as the tyres deposit these into the arches, so we must ensure this area is sufficiently flushed out, and most of the dirt is removed.

We then apply a solution of Nitty Gritty Pre-wash to the inside of the wheel arches. We recommend a solution diluted at 1:10 for this purpose. Once applied, we take our EZ Detail GO Brush and brush the inside of the arches. Now, if you are lucky, you'll have plastic-lined wheel arches. These are much quicker and easier to clean than carpet-lined arches, where more time and patience will be required to achieve perfect results.

Once satisfied with the wheel arch, we move on to the tyres. As we know, clean tyre walls are essential to achieve the best results whilst ensuring the durability of your new, freshly applied tyre dressing. For this stage, we use Cleanse - Tyre Cleaner. Cleanse is designed to remove any old or previously used dressings, grime and discolouration from the tyre wall surface. Cleanse penetrates deep into the tyre to break down existing products in preparation for applying new dressings.

Apply cleanse with the included trigger head, and spray a few times all around the tyre wall. Now using your Tyre Scrubbing Brush clean the surface of the tyre wall. The foam generated by this is a brown, muddy colour. This is all the grime and old dressings being broken down and removed. Once all of the tyre walls have been thoroughly cleaned, rinse and then repeat the process again until the foam produced is white, this is how to tell that all of the grime and old tyre dressing products have been sufficiently removed and the surface is primed for applying our new tyre dressing.

Now we turn our attention to the alloy wheel, the main event. We have already pressure rinsed off any loose surface dirt or dust so we can move straight into applying Axis - Non-Acidic Wheel Cleaner. Axis can be diluted as required, but a good starting point is 1:10.

Axis is a blend of intense cleaning and foaming agents combined with chemical compounds that bind to and dissolve brake dust and road grime on the wheel's surface. Axis is safe for use with all clear coated wheel finishes. We recommend testing on an inconspicuous area with bare metal or polished alloys. If you are unsure about dilution ratios, then our Duel Autocare Professional Dilution Spray Bottle, with dilution marks on the side, is the perfect accessory. The bottles flaunt a screen printed design complete with Duel branding and space to write on the bottle what it contains. Complete with a Tolco chemical-resistant trigger head, these solvent-resistant triggers will withstand most chemicals. The bottle is complete with moulded dilution markers ranging from 1:1 through to 10:1 to make the dilution of required products easy.

Take your EZ Detail Wheel Brush and clean the insides and barrels of the wheel. Apply a good amount of product to the wheel surface, ensuring all areas are sufficiently covered, including the barrels of the wheels. Once this area has been taken care of, clean the face of the wheel using your Detailing Brush, not forgetting the little intricate areas such as centre caps and wheel nuts/bolts, as these are often overlooked and can spoil your overall finish if not cleaned properly. Once satisfied that all areas are clean and brake dust-free, pressure rinse off all remaining suds or residues. Now, depending on the condition of the wheels beforehand, a stronger cleaning product may be required. This is where acid-based wheel cleaners come in handy, but please be careful and follow the instructions correctly, as, in the wrong hands, an acid-wheel cleaner can cause damage to your wheels.

Now, although the wheels may appear to be clean visually, however, there still may be some traces of contamination on the surface. Usually in the form of tar spots, picked up from freshly laid road surfaces, and these will appear on the surface as little black specks. If you locate tar spots, BlackJack Glue & Tar Remover will be required. Spray Blackjack to the required area and leave it to work for 2-3 minutes but do not allow it to dry. The tar spots will begin to run away. They can then be wiped away using a Duel General Purpose Cloth.

Iron Fallout is the next form of contamination that may need to be addressed. These are tiny ingrained iron particles generated by your brakes and brake discs. For this Toxin, Iron Fallout Remover will be required. Toxin works by securing and removing iron particles and contaminants whilst turning a characteristic purple colour. To apply this, we follow a similar process to Axis in the application and the tools we use to clean. Apply a good amount of product to the wheel surface, including the barrels of the wheels. Using your EZ Detail Wheel Brush and clean the insides and barrels of the wheel. Once this area has been taken care of, clean the face of the wheel using your detailing brush. You will see the contaminates being removed as the reaction generates a purplecolouration, which is quite visually pleasing!

It's important to note that this step is unnecessary each time you clean the wheels. We would suggest once a month is sufficient. Once complete, pressure rinse away any remnants of product or residues.

Now it's a simple case of repeating all these steps for each wheel before moving on to your pre-wash and contact wash process.

Once you have finished all exterior cleaning steps, you can move back to the wheels to dress the tyres in your chosen tyre dressing. We would recommend Duel Autocare Profile - Tyre & Trim Dressing. Profile is a multi-gloss level tyre and trims dressing for all rubber and plastic exterior surfaces. A solvent and silicone blend offers a durable, quick-drying and water-repellent finish to your tyre walls and your vehicle's plastic trims. The beauty of Profile is we can choose our desired finish for the tyres by layering Profile, one initial layer will leave a satin factory finish, and additional layers will result in extra gloss. More layers equal more shine. The choice is yours!